Materials know-how

White ceramic is about nine times harder than steel, meaning the manufacture of the Royal Oak Concept GMT Tourbillon’s bezel, push pieces, crown and especially its intricately shaped upper bridge was a complex and lengthy process.

Ceramic is an almost totally scratch-proof composite material that can be scratched only by diamonds, calling for the use of special milling-cutter machines equipped with diamond-tipped tools. Treating the roughed-out surfaces and edges to a polished or satin-brushed finish represents a daunting technical challenge, due to ceramic’s inherent resistance to abrasion. It takes around 8 hours to make the Royal Oak Concept GMT Tourbillon’s bezel, compared with 45 minutes if it were steel, calling upon all the savoir-faire of the watchmakers and engineers. As well as giving an exceptionally smooth final appearance, ceramic has a practical purpose, displaying extreme resistance to wear.

Similarly, the titanium used for the case middle and sapphire surround is ultra strong, comfortable to wear twice and as light as steel – advantageous for a watch of such generous 44mm proportions. Further demonstrating Audemars Piguet’s deeply entrenched knowledge of high-tech metals and materials, the inner flange circling the dial is made of lightweight aluminum, hardened by anodization.

This daring cocktail of ceramics and metals is just the latest chapter in Audemars Piguet’s ongoing quest to push the envelope when it comes to materials science —a quest that started over 40 years ago with the Manufacture’s most daring move of all, using steel in a luxury watch for the very first time.

Technical tour de force

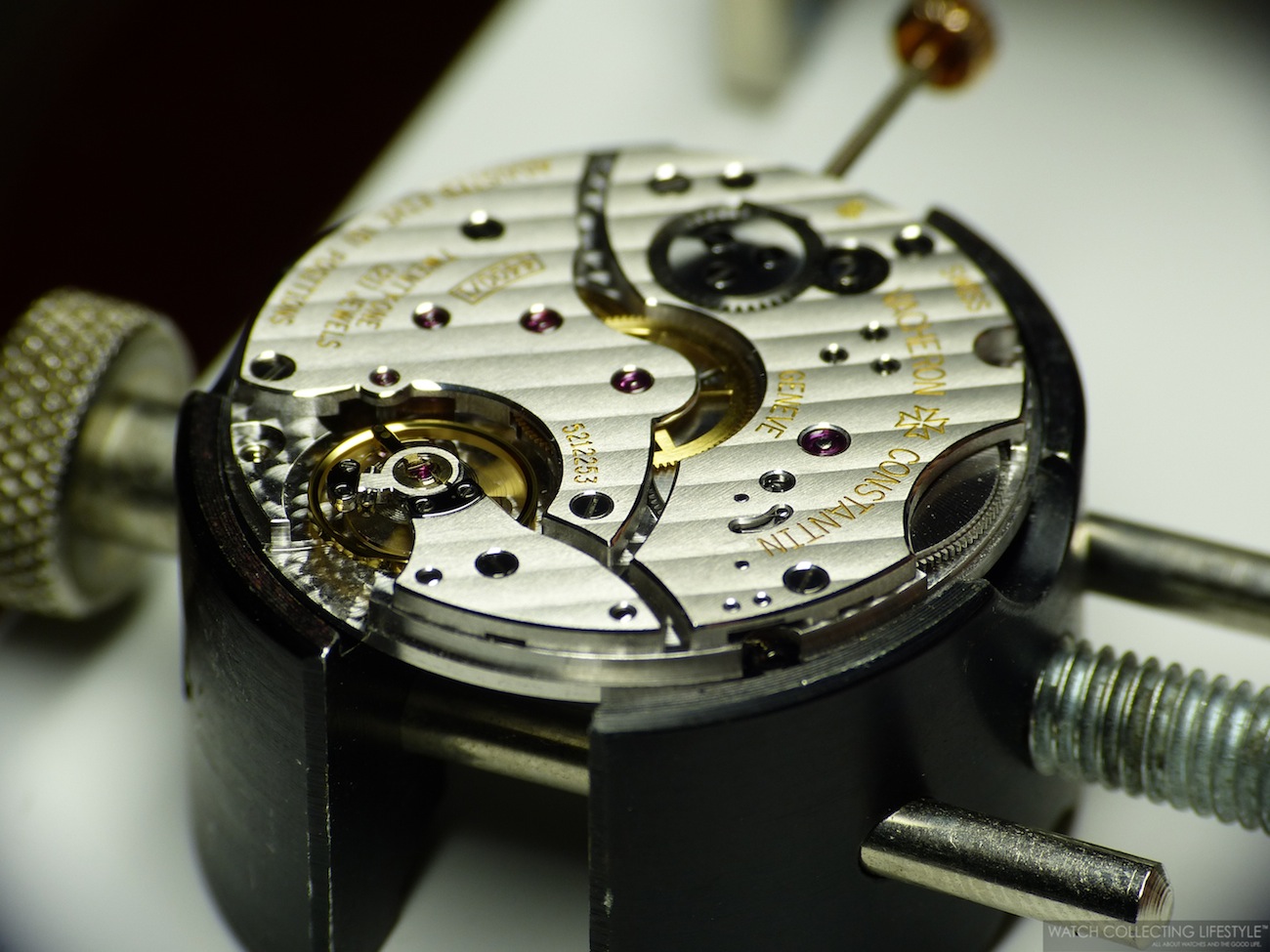

The defining characteristic of Audemars Piguet’s Concept watches has always been the coherence of case and movement. The ultra-modern ‘engine’ is seamlessly integrated within its ultra-modern ‘chassis’, whose techy aesthetic perfectly complements and showcases the exposed micro-mechanics.

An impressive feat in its own right, the Royal Oak Concept GMT Tourbillon’s hand-wound Calibre 2930 features a twin barrel ensuring 10-day power reserve, tourbillon and second time-zone ‘GMT’ display.

Its timekeeping is regulated by a 3Hz (21,600vph) escapement, rotating inside a tourbillon carriage every 60 seconds, compensating for the effects of the Earth's gravity when the watch is oriented vertically for any length of time.

The tourbillon cage comprises 85 components, yet only 0.45g in weight. An experienced watchmaker spends almost three days assembling its 85 components, including two full days to install the cage, while the full workings will require over two weeks of work. Audemars Piguet is still one of the few manufactures to have mastered all the intricacies of this complication, with over 25 different movements featuring a tourbillon. Each component is beveled, polished, assembled and balanced by hand.

The GMT display provides an instant reading of the time in a second time-zone. It is adjusted using the push piece at 4 o’clock (one press adjusts the time by one hour). The indication of the second time-zone, based on 12 hours, comprises two superimposed discs, making it easy to tell the time. The first, on which the figures are inscribed, completes one turn in 12 hours. The second, just below, completes a turn in 24 hours and has 2 colored areas: a white half for daytime and a black half for night-time. This makes it easier to read the figures.